Sand washing machines play a certain role in washing and selecting in many stone production lines. Sand washing machines can easily remove impurities on the surface of sand and gravel aggregates. In addition to those sand making production lines and sand and gravel production lines, sand washing machines are required. There are many other operations for washing minerals, and I will introduce them to you below:

First, there is a big difference in the selectability between the original slime and the ore of some ores. By using a sand washing machine to separate the mud and sand and process them separately, better selection indicators can be obtained;

Second, the ore needs to be manually selected or photoelectrically selected, and the sludge contaminates the surface of the ore, making it difficult to identify. At this time, a sand washing machine must be used to wash the ore before hand selection or photoelectric selection;

Third, hematite and limonite contain a lot of clay. If the cement clay contains very little iron minerals, the mud can be discarded as the final tailings after washing with a sand washing machine, and the grade of the resulting ore will be can be greatly improved;

Fourth, the ore contains a lot of mud, which often blocks the fine crusher, screen and ore port, making the production line process or production operations difficult to continue. It can be processed by the sand washing machine ore washing method.

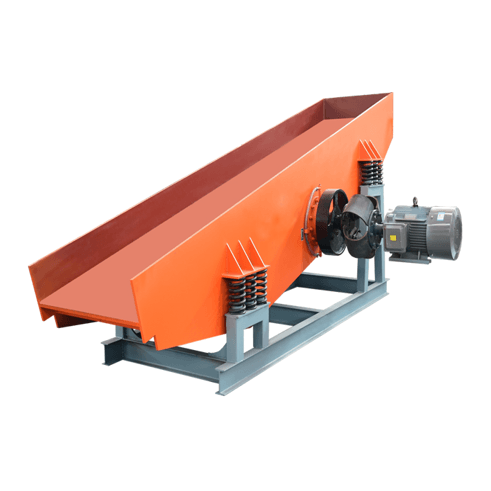

The company mainly produces various types of mining machinery products such as vibrating screens, feeders, conveyors, sand washers, crushers, fine sand recovery machines, sand making machines (high-pressure roller mills), dewatering screens, trommel screens, etc. And its supporting accessories are widely used in mining, cement, highway, high-speed rail, metallurgy and other industries.