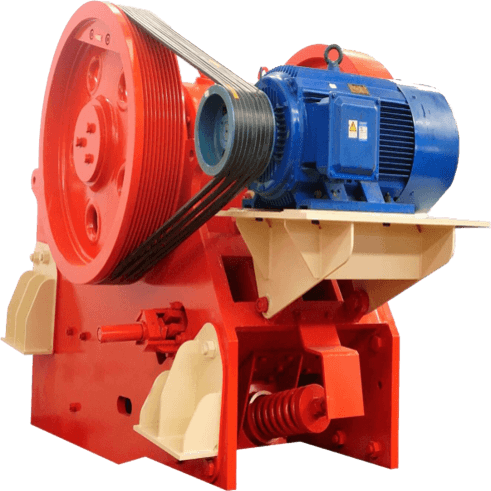

Working principle and features:

1. Modular non-welded structure: Improper welding can change the performance of the crusher material, affect the overall life of the crusher, cause unnecessary maintenance, and delay production. The new crusher uses front and rear binning’s that are separately cast with side plates, integral bearing seats, and connected by pins. And make the transportation of the crusher more convenient.

2. Integrated motor installation: The motor frame is already installed on the crusher when it leaves the factory. The motor frame and the crusher are integrated, which reduces the installation space and V-band length of the crusher. The synchronous movement of the motor and the crusher increases the life of the v belt.

3. Finite element analysis: The crusher adopts the industry’s professional mechanical equipment software to assist in the design. From component modeling to mechanism analysis, from dynamic analysis to finite element analysis, the entire process of design has been effectively controlled.

4. Optimization of the crushing cavity: the optimal design of the crushing cavity and the reasonable stroke make the output of the crusher higher. Whether it’s pebbles, quarry stones or ore, there’s a bite plate to match.

5. More convenient adjustment: easy to dry and realize automation: the new crusher adopts wedge plate adjustment. Mechanical adjustment allows the crusher to be adjusted whether it is working or stopped. After changing to liquid pressure adjustment, the crusher can be automatically controlled, and adjustment and movable jaw preload can be realized by just touching the button.

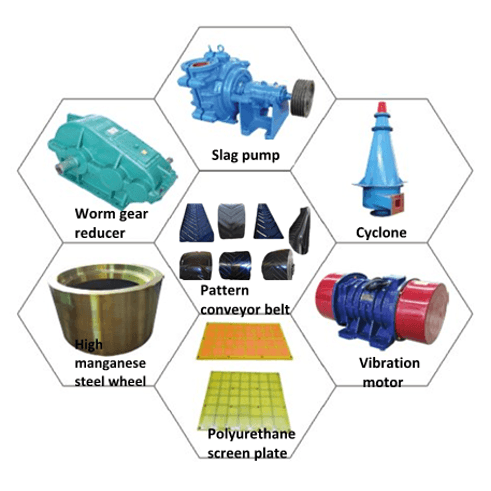

6. Optional accessories: PEV series crushers provide a variety of optional accessories, including feeding hoppers, safety covers for flywheels, automatic lubrication systems, and hydraulic adjustment systems. These optional accessories can greatly improve the operating efficiency of the equipment and reduce production costs.

7. Structural optimization: The mechanism analysis is used to optimize the stroke of the movable jaw to obtain a larger stroke than ordinary crushers, so the output is higher, and the efficiency is higher.

8. Production and processing: PEV series crusher parts are made of high-quality alloy castings and hot-rolled alloy steel plates to ensure long service life.

9. Enlarged bearings: The new crusher adopts 4 bearings of the same size, which are larger and have a longer service life than other crushers of the same specification. The maintenance time of the movable jaw assembly is reduced, and the cycle of replacing the bearing is prolonged.

10. Discharge port liquid pressure adjustment system (manufacturing): each type of crusher can be equipped with a hydraulic adjustment system, through the cooperation of the hydraulic pressure cylinder and the accumulator, to automatically adjust the discharge port and pre-tighten the purple movable jaw the goal of. The safe and reliable hydraulic system reduces the preparation work before starting, improves work efficiency, and ensures the safe operation of the host machine.