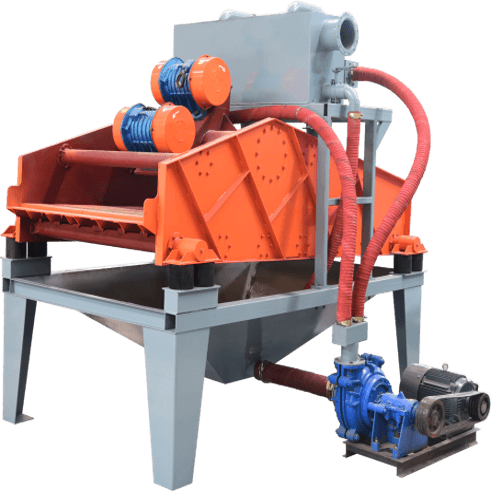

The sand-water mixture is sent to the mud-sand high-pressure separator by the slurry pump, and the tailing sand concentrated by centrifugal classification is provided to the dewatering screen through the grit settling nozzle. After dehydration by the dewatering screen, the tailing sand and water are effectively separated, and a small amount of tailing After returning to the cleaning tank through the return box, if the cleaning tank is too high, it will be discharged through the discharge port. The weight of the recovered material from the dehydration screen is concentrated to 70%~80%. The adjustment of the fineness modulus can be achieved by changing the pump speed, changing the density of the sand paddle, adjusting the overflow water volume, and replacing the sand outlet, to complete the three stages of cleaning, dehydration, and classification. function.