World most Reliable Advantages of Double Boring and Double Welding Rollers

Roller Introduction

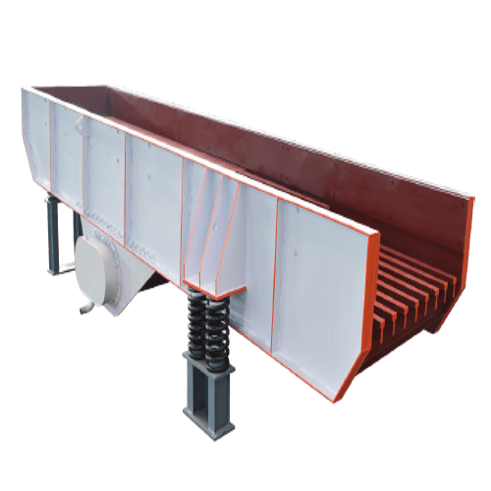

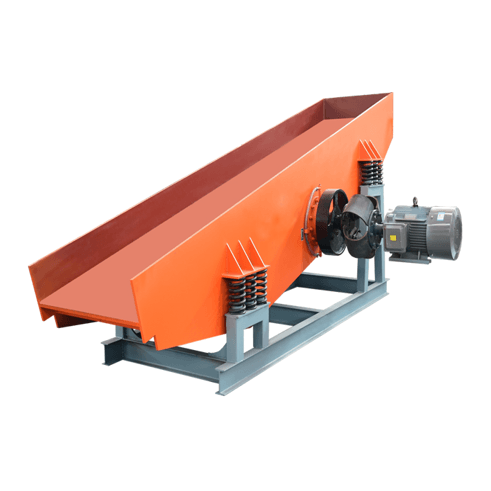

Roller is the main component of a belt conveyor, used to support the conveyor belt to reduce running resistance and ensure that the belt sag does not exceed the specified limit to ensure smooth operation of the conveyor It is widely used in several types of belt conveyors in industries such as coal mining, metallurgy, and building materials etc. Our factory has introduced advanced roller dedicated production lines and supporting specialized processing equipment to achieve large-scale and specialized processing and assembly, its characteristics are the roller rotates flexibly, has small starting resistance, good sealing performance, long service life, small maintenance workload, strong carrying capacity, and is an ideal accessory for belt conveyors.

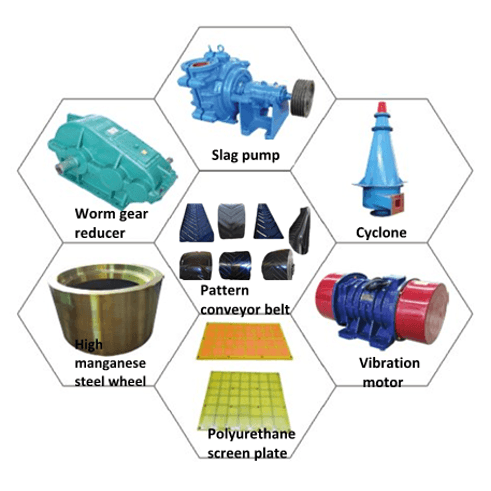

Our products include a series of grooved rollers, flat rollers, buffer rollers, conical rollers, etc.

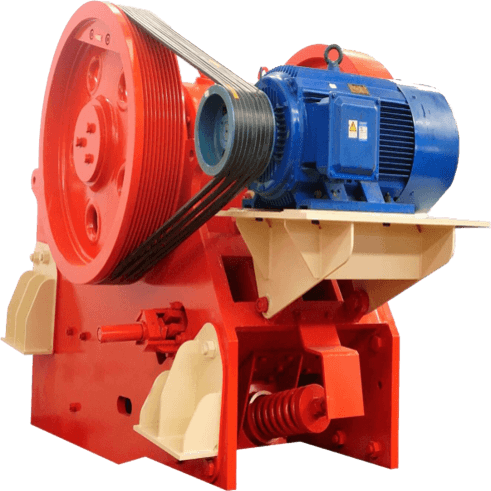

Our company has introduced a horizontal double boring lathe to process pipe fittings, ensuring concentricity. The double welding machine tool is also used for welding, ensuring that the technical parameters remain unchanged

Advantages of Double Boring and Double Welding Rollers

1. The use of a labyrinth seal ensures that the lubricating oil is not oxidized, not lost, not immersed in water, and not immersed in dust

2. After double boring and welding, the concentricity is ensured, and the normal operation resistance is small, thus saving electricity and improving the service life

After-sale service

If the user complies with the storage, transportation, installation, and not overload the conveyor, and the carrier roller is damaged or unable to function properly due to poor manufacturing quality within 3 months of use, the manufacturer shall promptly repair or replace it for free.